The two Ferdinands

The Pietro Bazzanti Gallery in Florence was purchased by the Marinelli family in 1960, family that owns the Ferdinando Marinelli Artistic Foundry in Florence. And it is thanks to the “two Ferdinands”, as it is narrated below, that the Foundry and the Gallery met and joined.

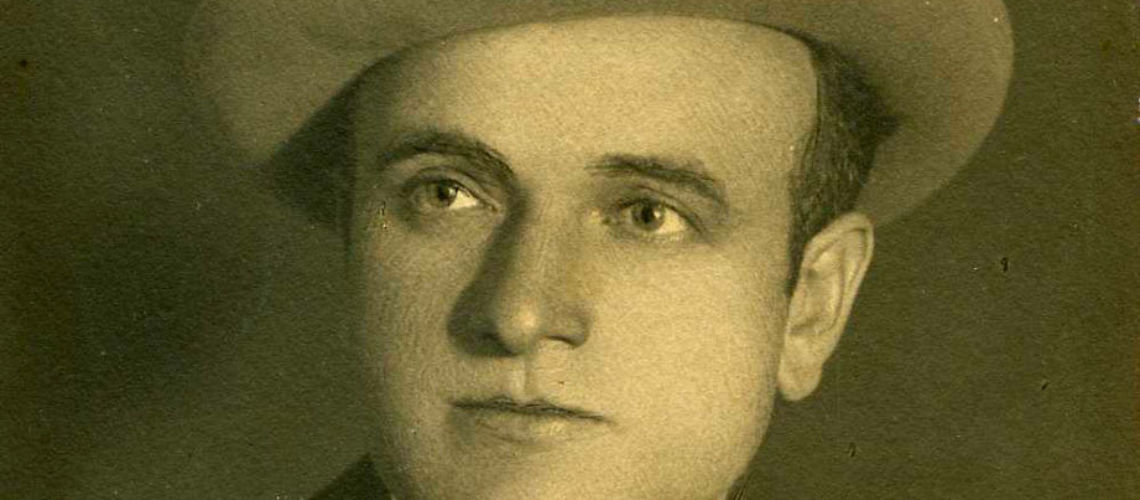

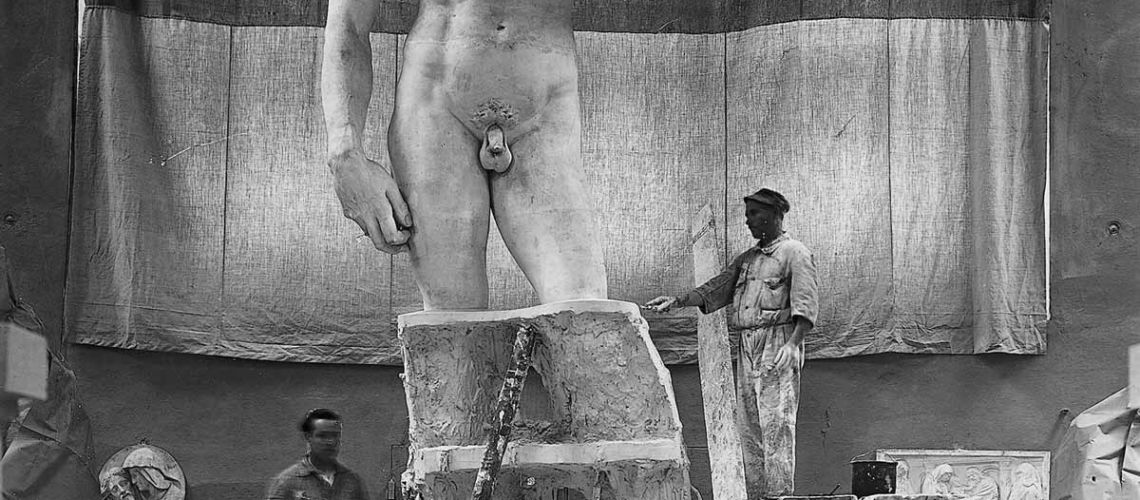

Ferdinando Marinelli Senior went down, at the beginning of the 20th century, from Umbria to Florence when he was a young boy, to learn about the art of lost wax-casting that he then learned in foundries which, starting with Giambologna, went from father to son.

In 1919 he took over the Gabellini foundry of Rifredi (Florence), transforming it into the Ferdinando Marinelli Artistic Foundry

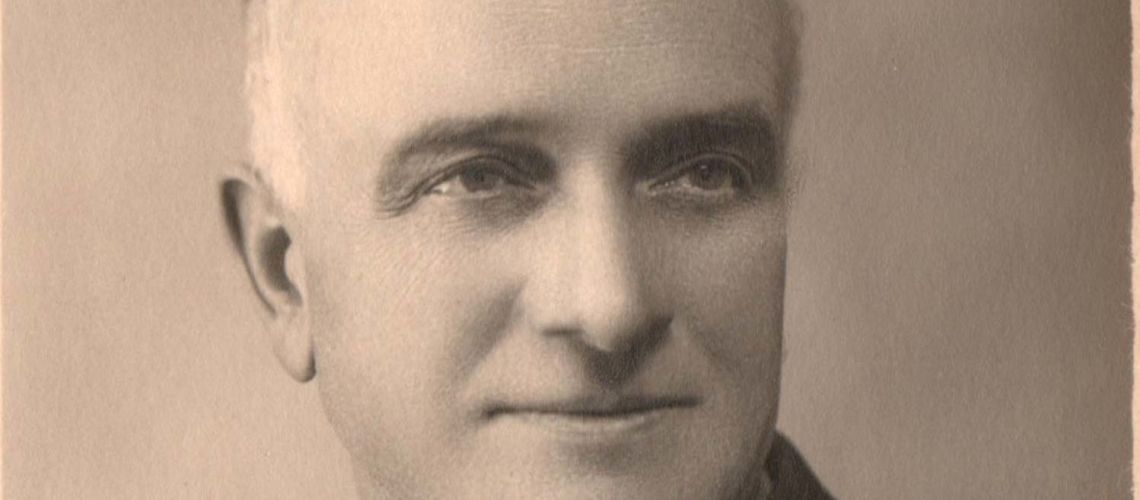

He married Delia Gelli from whom he had two sons, the eldest of whom, Marino,

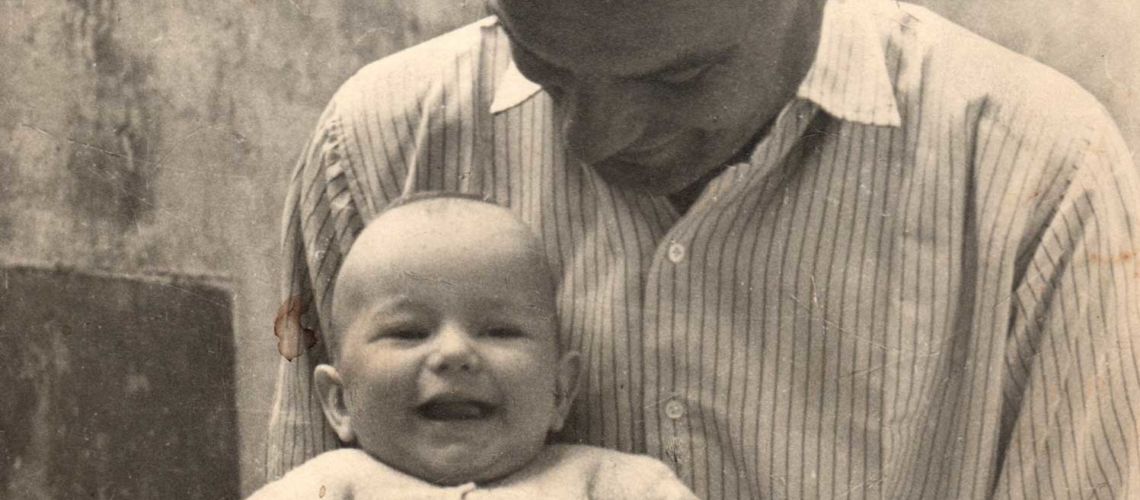

will continue with his brother Aldo the melting activity. Marino married Renee Naylor, and in 1949, shortly after Ferdinando Marinelli Sr. together with his wife Delia were at the thermal Baths of Montecatini,

Ferdinando Marinelli Jr. was born.

In 1976 Marino died, and the Foundry passed to Ferdinando Jr.

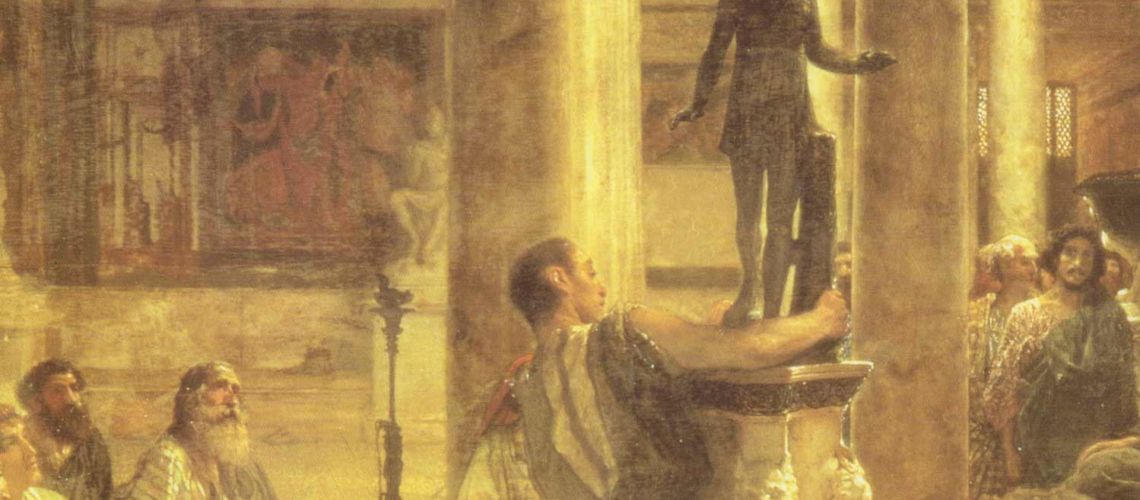

The Foundry was run by Ferdinando Sr. in a patriarchal manner, almost a large family and hovered in an atmosphere of a Renaissance workshop.

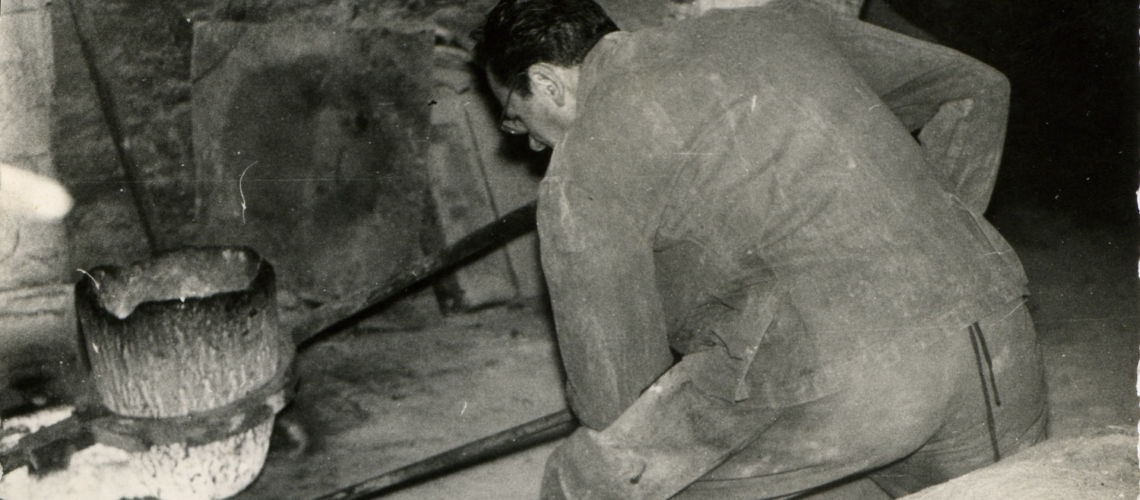

Ferdinando Jr. very often visited the foundry, enchanted by the work of the artisans, and as every child is able to do, he learned on the fly without realizing those ancient techniques. And the materials were beautiful and strange and with mysterious names, the plaster, the cat powder (ground alum), the soap mixed with oil, the red wax, the “loto” (fireclay), the sulfur liver, the lacquer of the Angels.

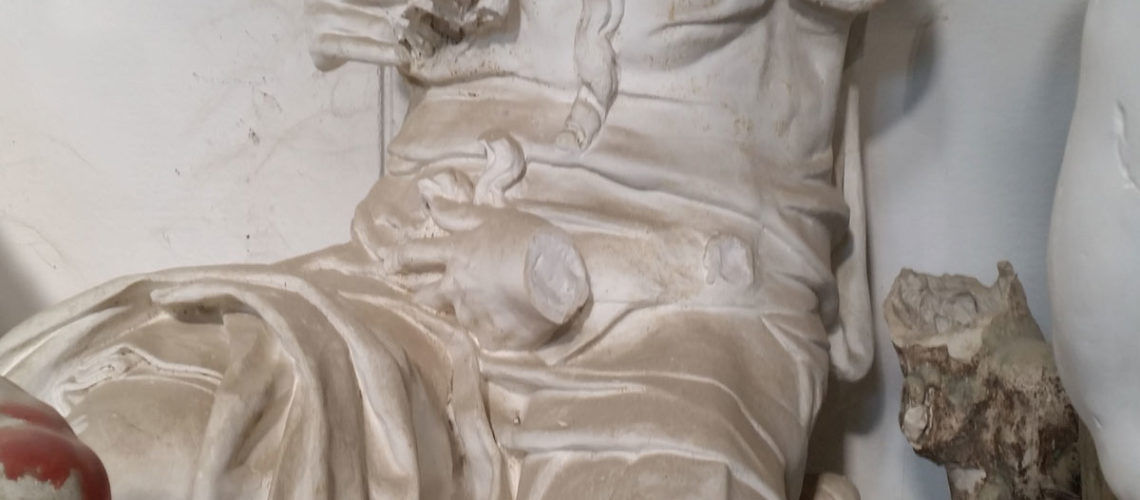

To create negative molds was used a strange gum that became semi-pasty in a bain-marie and that smelled tremendously, obtained by mixing the rabbit bone jelly with glycerin: the silicone resins were invented twenty years later. The wax that was brushed inside these negative mold was wax of bees (the paraffin suitable for this type of work did not exist yet), and sent a very good sweet smell.

Ferdinando Jr. had some difficulty in understanding that strange three-dimensional network of wax sticks with which the wax sculptures were imprisoned,

and why they were locked up in that refractory material they called “loto”, that means mud

and then left to cook for a long time day and night in those strange stoves which were built with bricks and clay directly above the lotus forms.

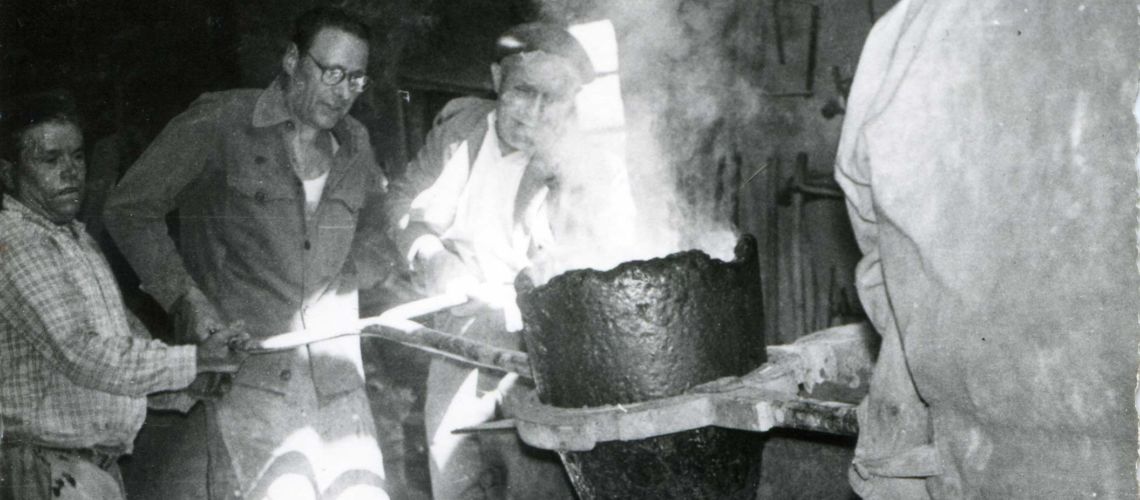

The bronze melting and casting was an almost sacred act, it was difficult for him to assist, and when it happened he had to stay still and good on one side, otherwise they would have given him a kick in his ass. The oven was a hole in the ground filled with coal with a fan that blew continuously, into which the crucible filled with bronze ingots was inserted. It took a few hours for the metal to melt. The casting was performed by hand, raising the crucible with inside more than 200 kg. of metal at about 1000 centigrades pouring it with precision inside the forms. Ferdinando Jr, had to stay at a distance because if one of the four workers holding the crucible had slipped, the mass of melted and incandescent metal would have splashed everywhere.

The molds of “loto” with the bronze statues just poured inside were split by hammer to extract the castings.

And then there were the bronze workers, some with green hair due to the copper contained in the bronze, each one was a character, jealous of their chisel engravers.

When the welders lit up the cigarettes held between their lips with the oxyacetylene flame to weld, Ferdinando Jr. ran away, convinced that they would have volatilized also their nose.

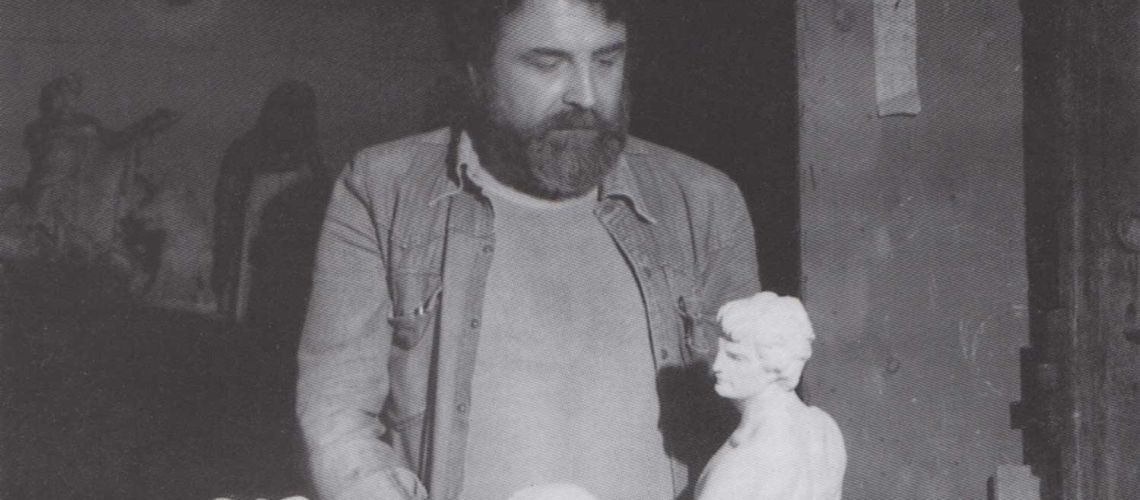

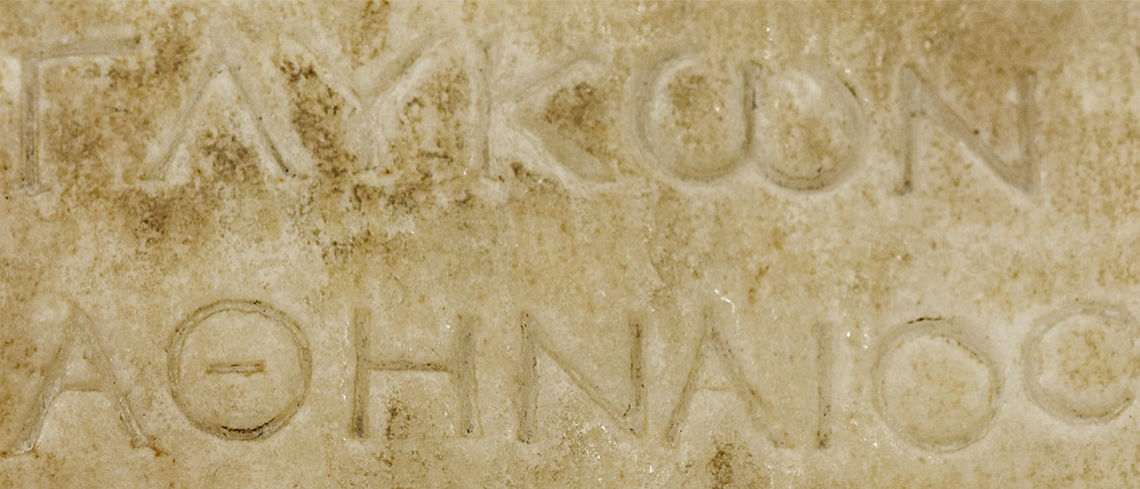

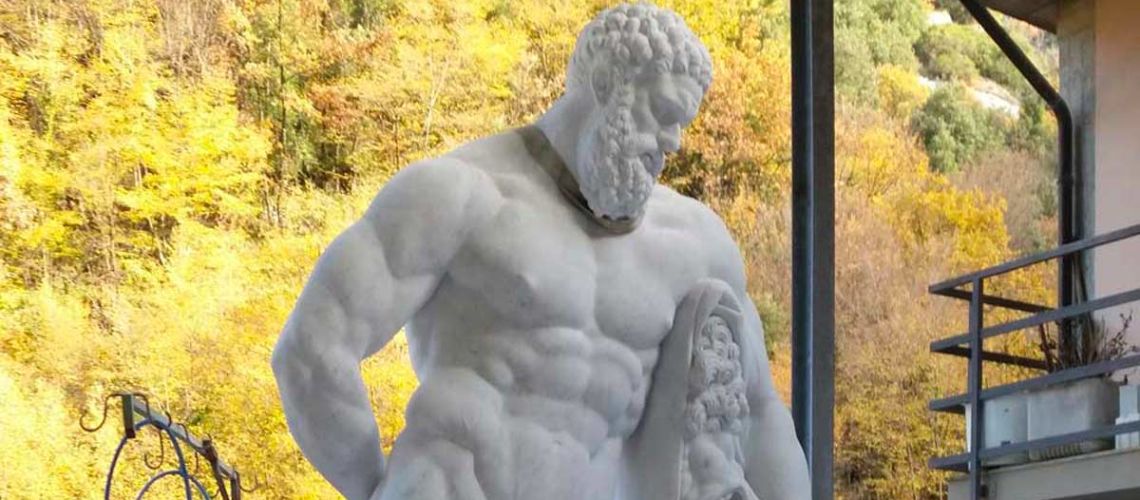

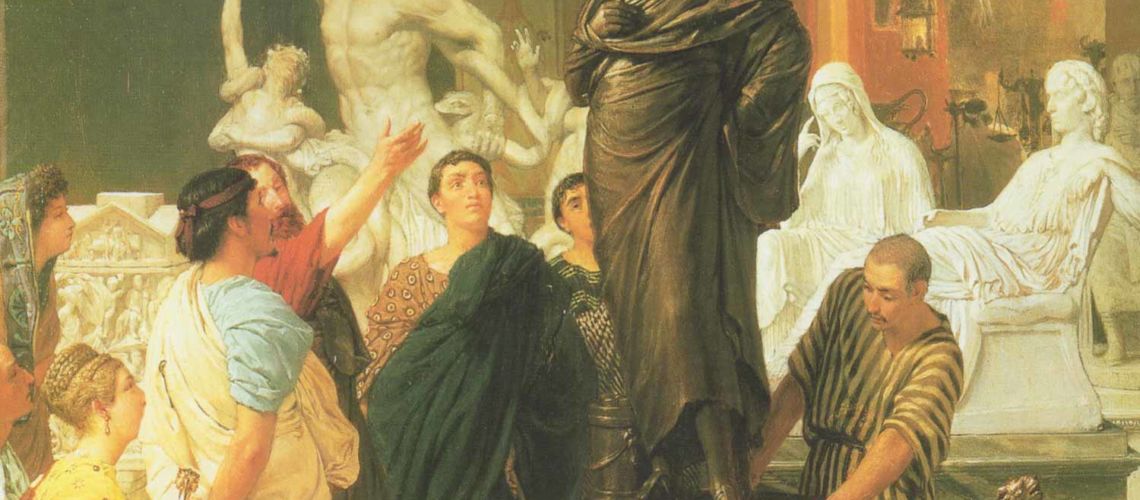

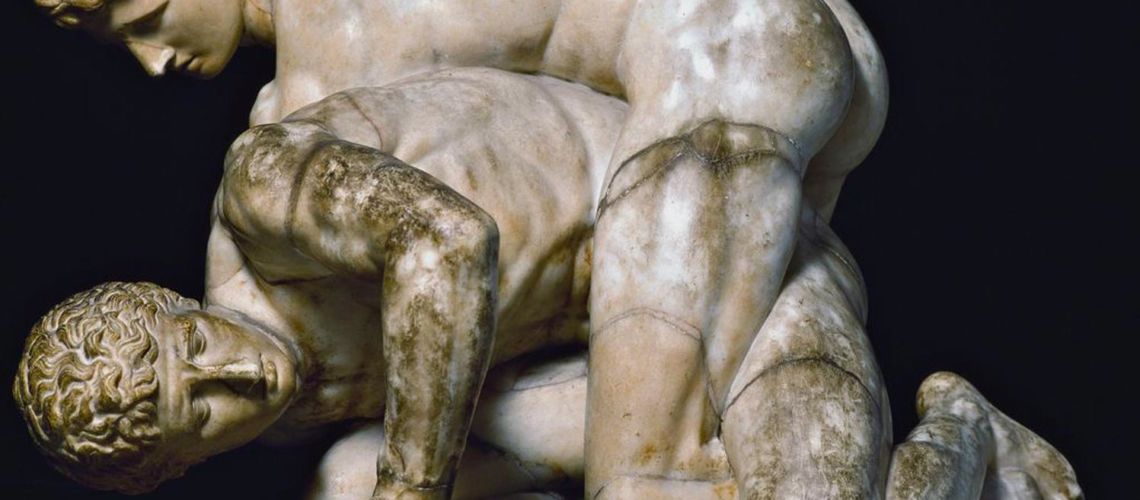

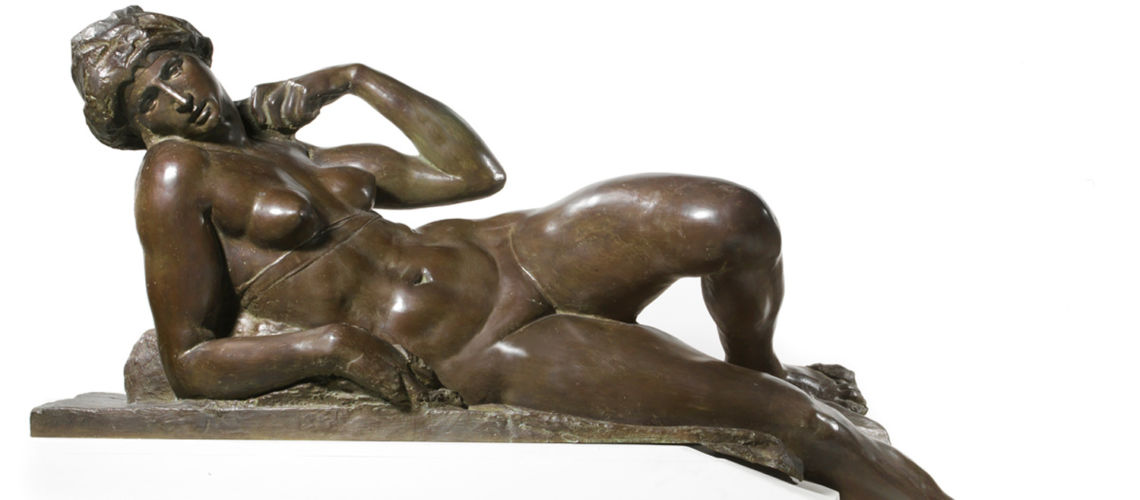

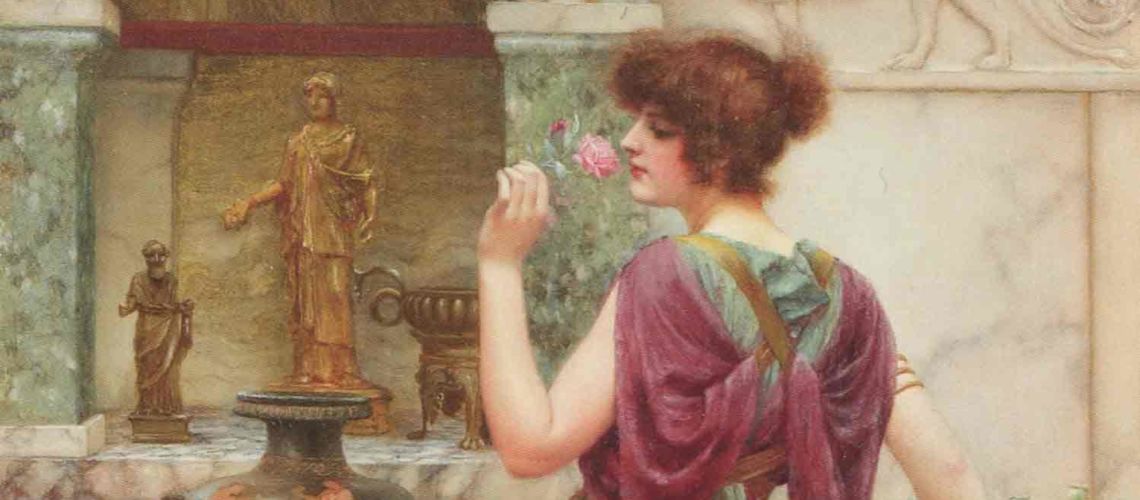

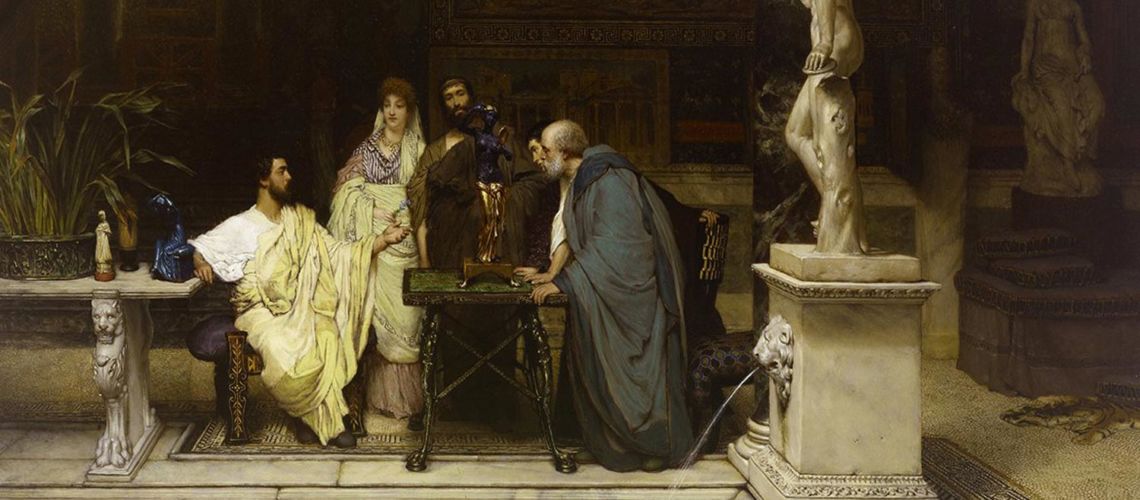

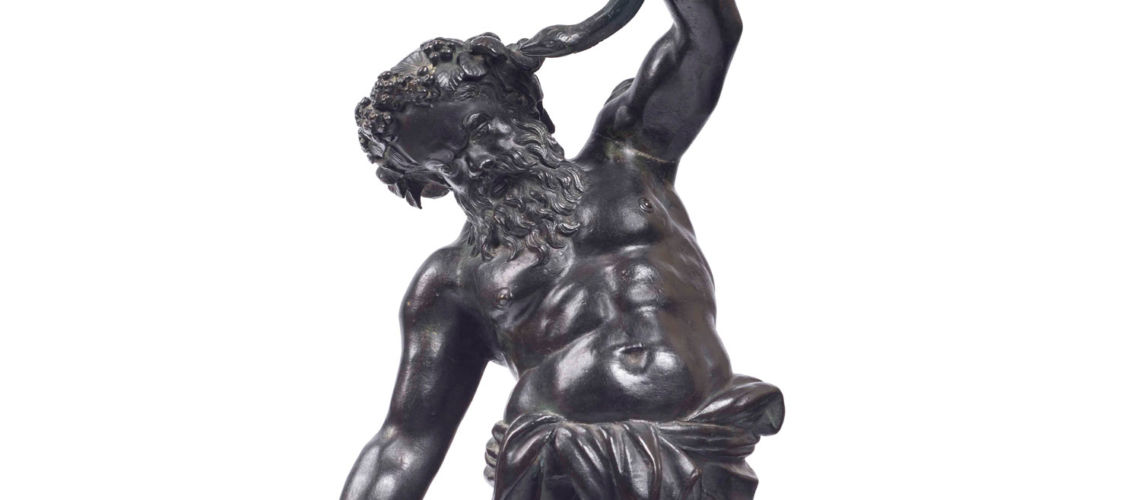

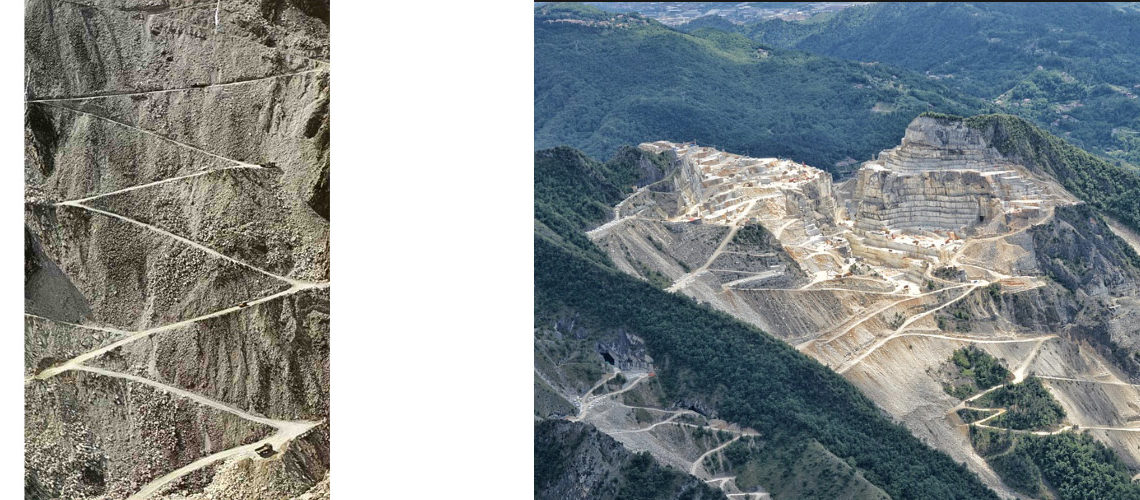

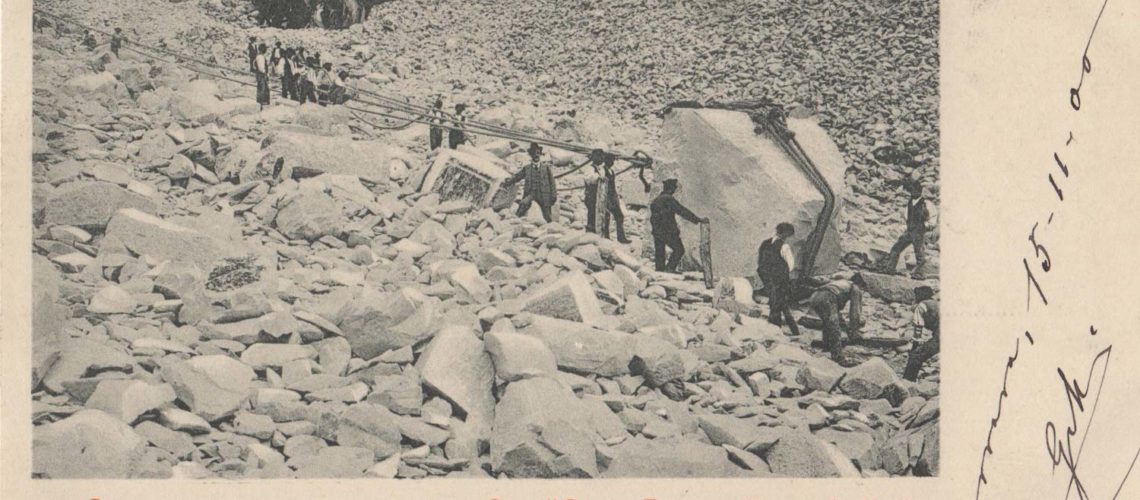

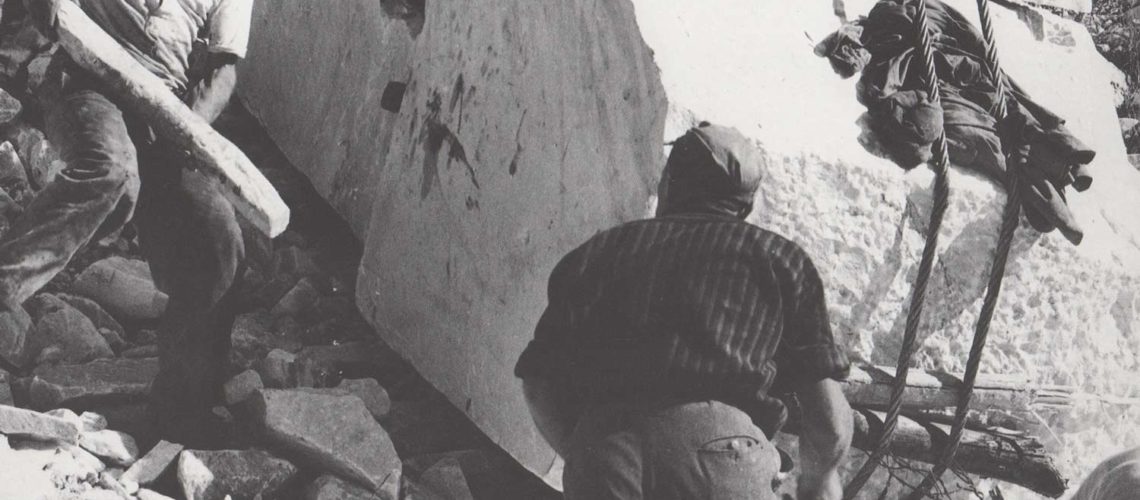

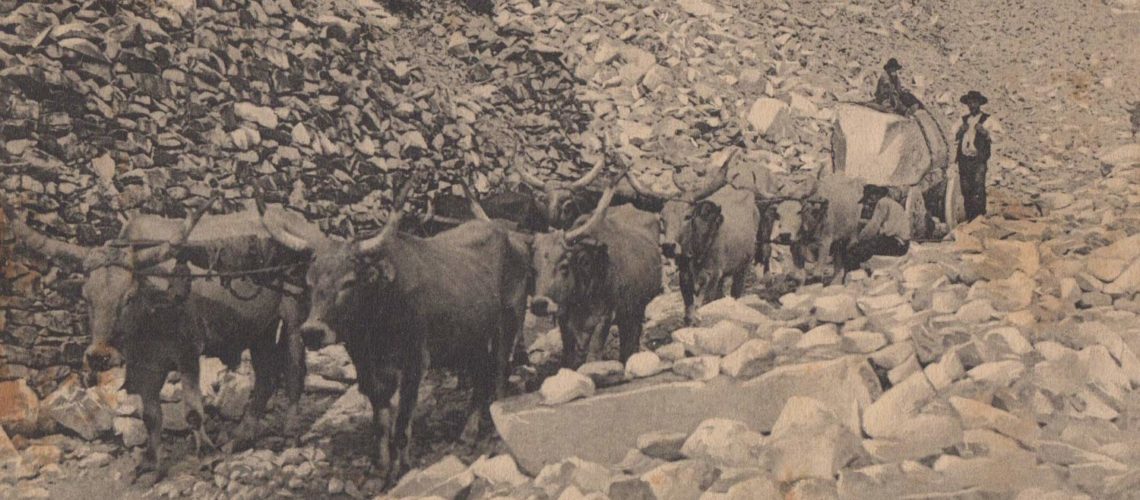

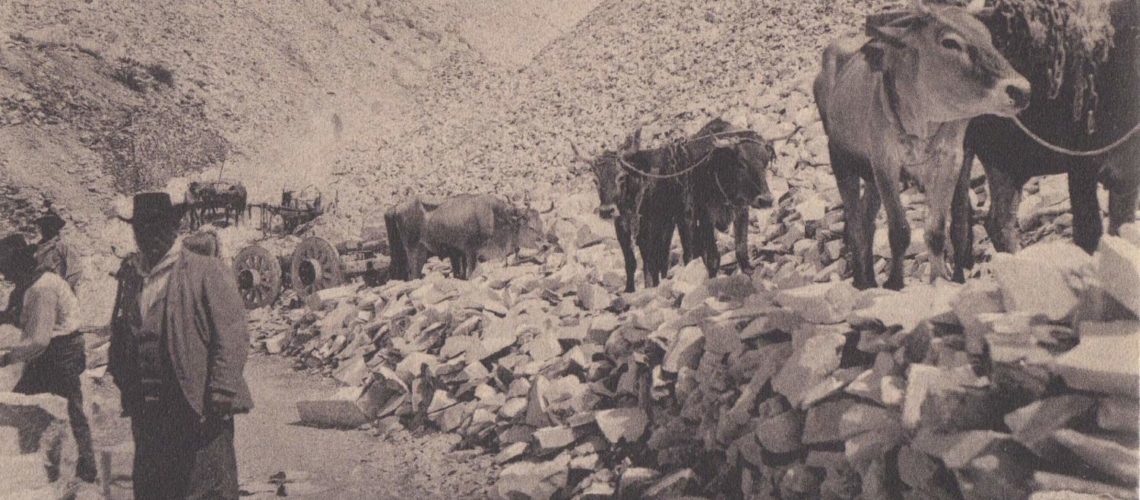

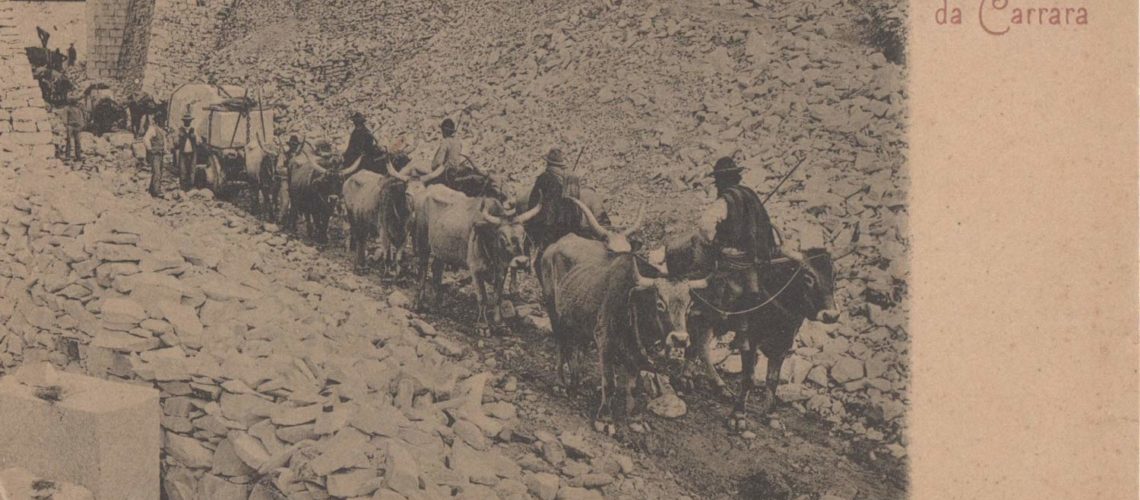

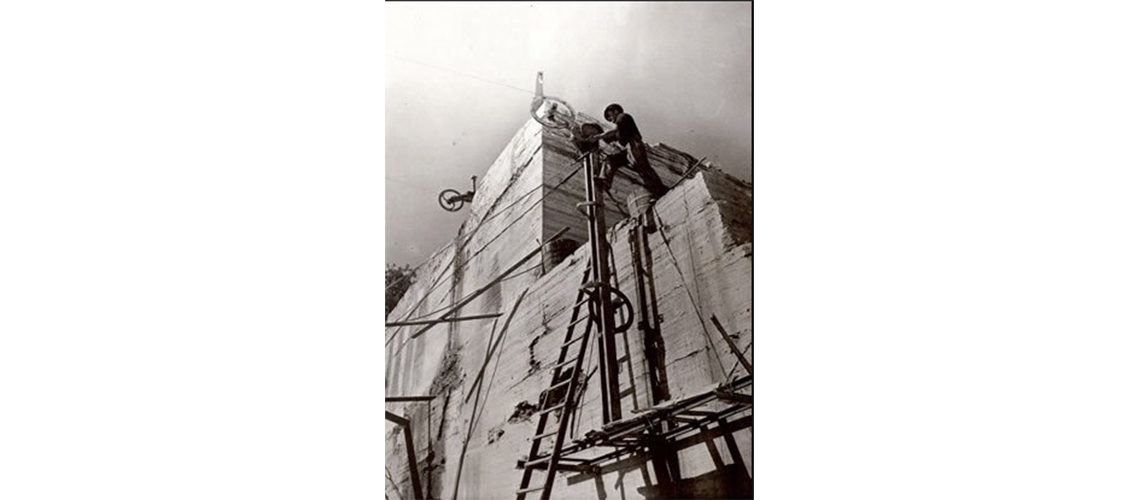

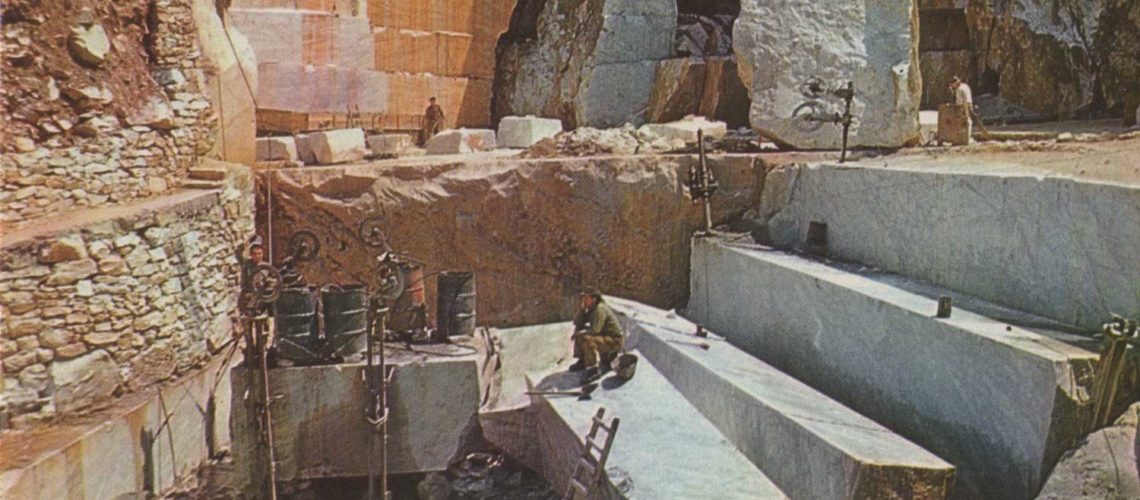

In 1976, when his father Marino died, Ferdinando Marinelli Jr. also became the owner of Galleria Bazzanti, which, in addition to sculpting his famous marbles in his studios in Carrara and Pietrasanta, sold bronze sculptures cast in the Foundry, in particular the replicas of the Ancient and Renaissance classics, of which he possesses the negative molds executed in the past on the originals by Ferdinando Marinelli Sr.