The Chisel

Part 2

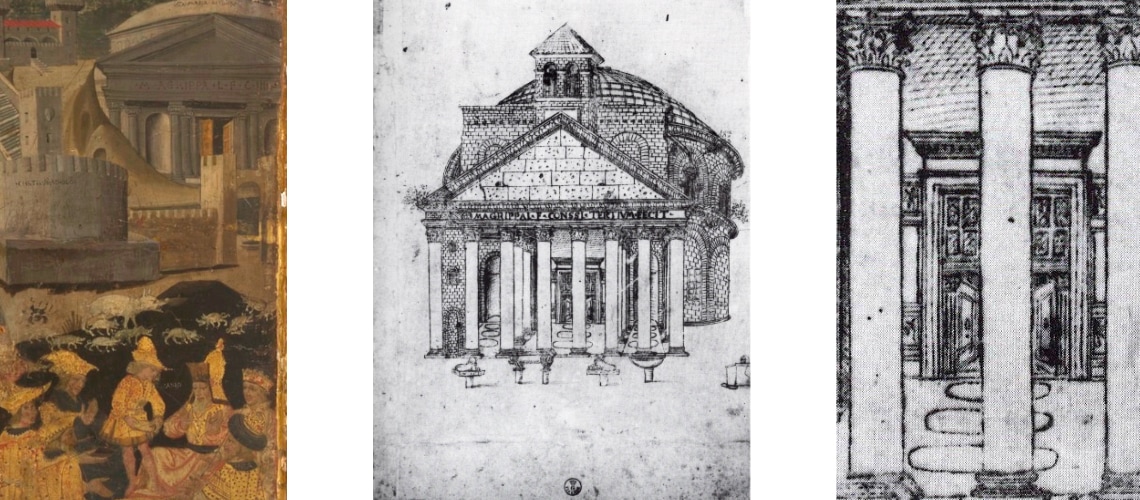

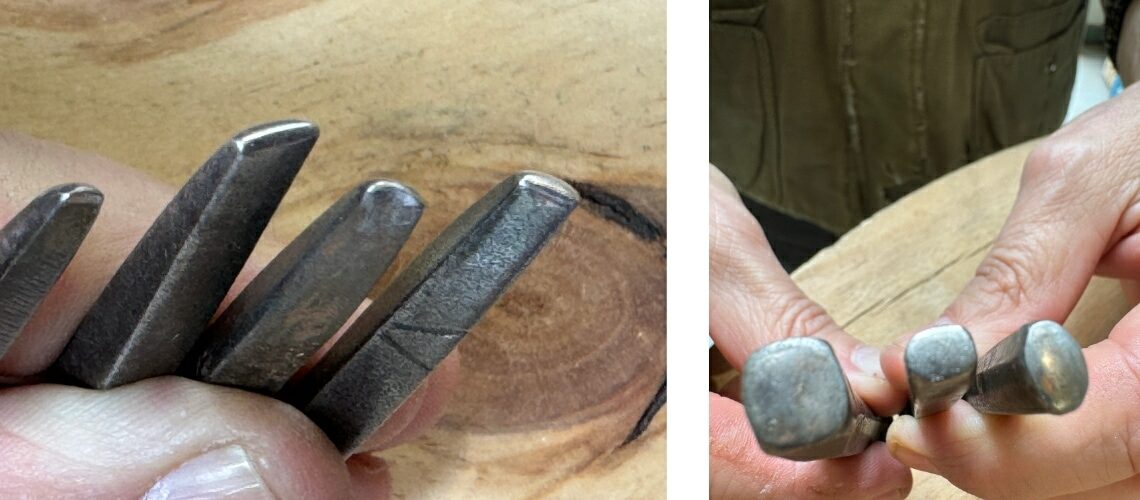

Chiseling hammers are different from common hammers, they have a different shape (Photo 1), a different weight (generally around 100 grams, handle included) with a flat and wide head (Photo 2) which is worn out by continuously hitting the iron (Photo 3), and a special balance so as to tire the hand of the chiseler as little as possible who must continuously hit the chiseling iron for entire days of work (Photo 4).

|

Photo 1 |

Photo 2 |

|

Photo 3 |

Photo 4 |

The iron is held between the thumb, index finger and middle finger, while the ring finger rests firmly on the surface to be chiseled (Photo 5,6).

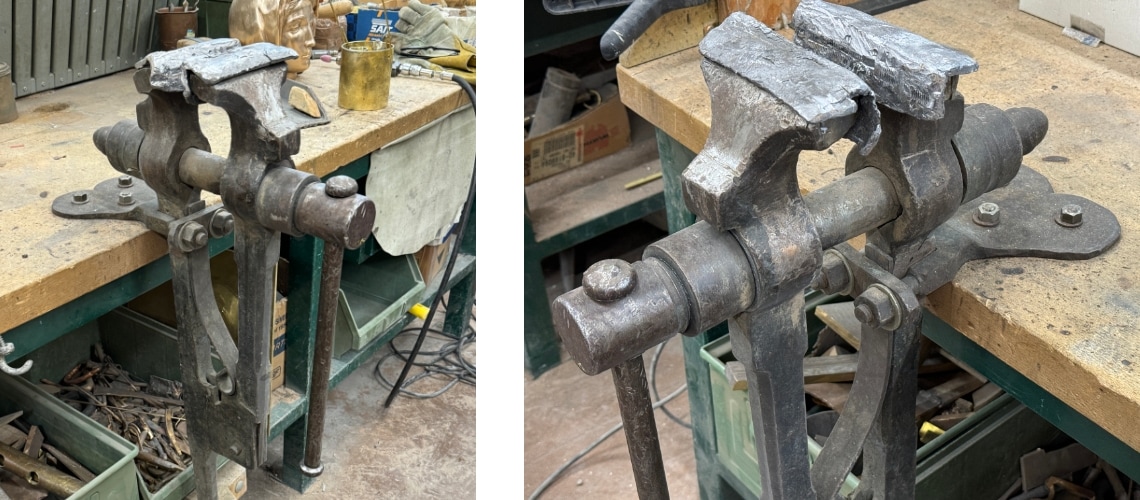

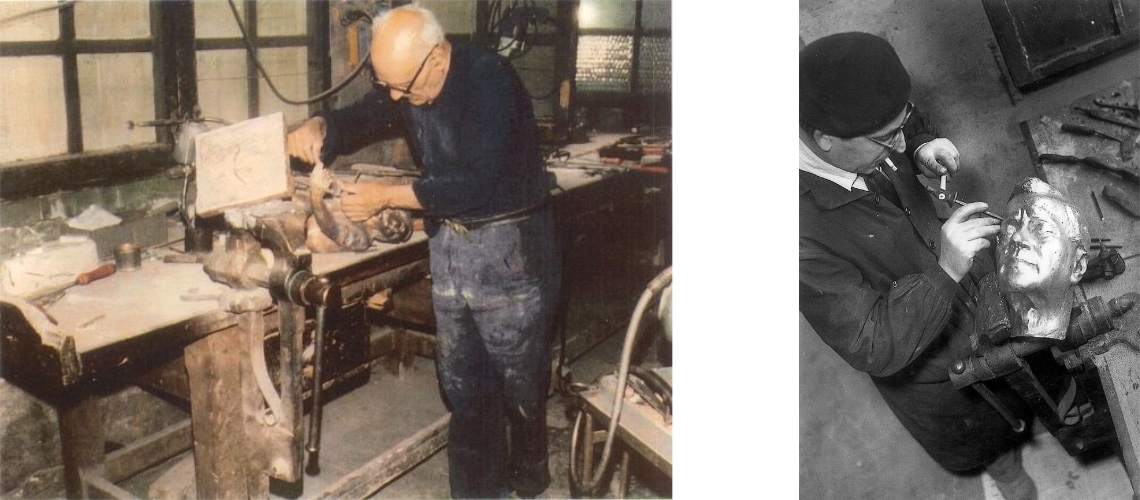

For chiseling, large sculptures are fixed on wooden supports; medium-small sculptures are instead stopped by the jaws of special “chiseling vices” (the vices in the images date back to the 1930s (Photo 7,8)) which have the characteristic of discharging to the ground the continuous blows created by the beating of the iron in the chiseling; the vices have lead jaws that allow the bronze sculpture to be tightened and blocked without causing scratches or nicks.

|

Photo 5 |

Photo 6 |

|

Photo 7 |

Photo 8 |

These clamps are applied to sturdy work worms (Photos 9,10,11) that have remained the same since the early 1900s to the present day.

One of the problems that chiseling bronze involves is the noise: a continuous “den den” at high volume that lasts for many hours, with few intervals of peace (as it’s possible to hear in the two videos below where the volume of the noise has been deliberately reduced), and which forces the chiselers to use noise-cancelling headphones.

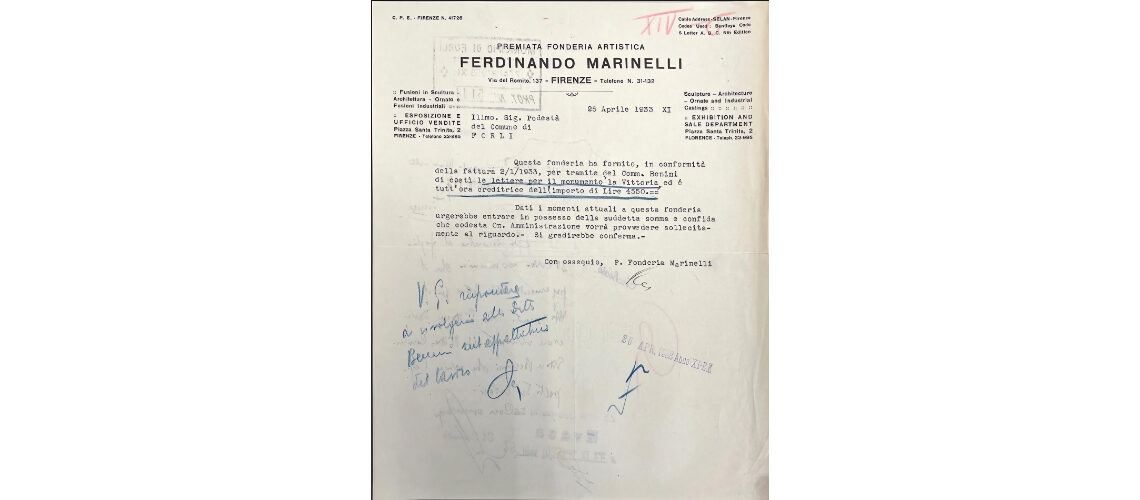

In the Ferdinando Marinelli Foundry in Rifredi, opened in 1919 between the houses, 3 to 5 chiselers have continued to chisel simultaneously every day. And it was precisely this noise that was one of the reasons that pushed us to create a new foundry in the countryside of Barberino Val d’Elsa where we moved in 2000.

|

Foto 9 |

Foto 10 |

Foto 11

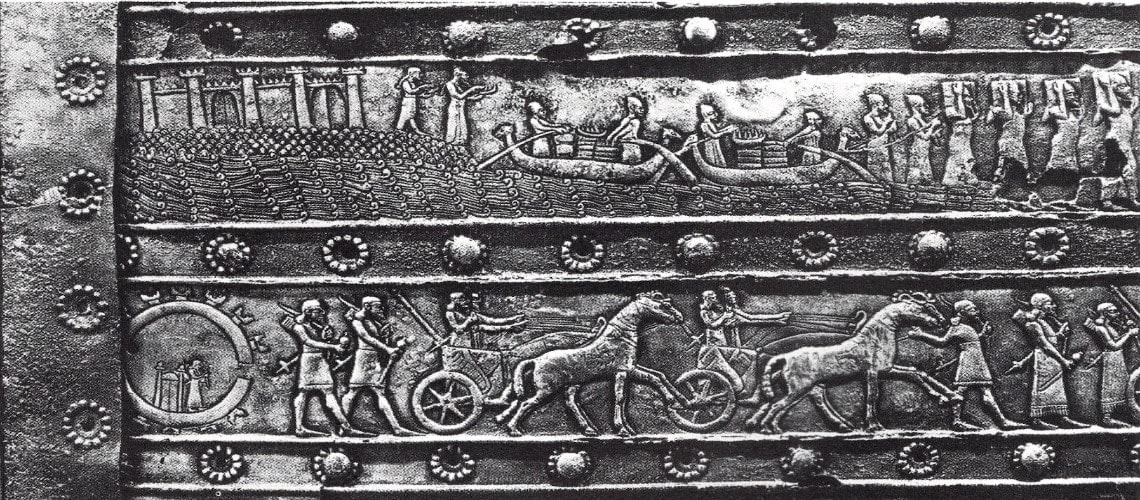

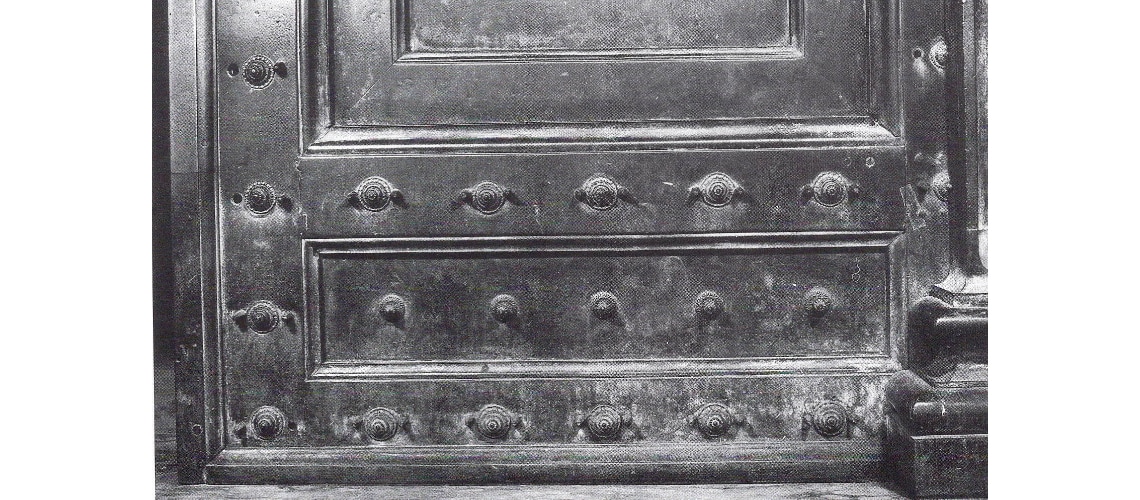

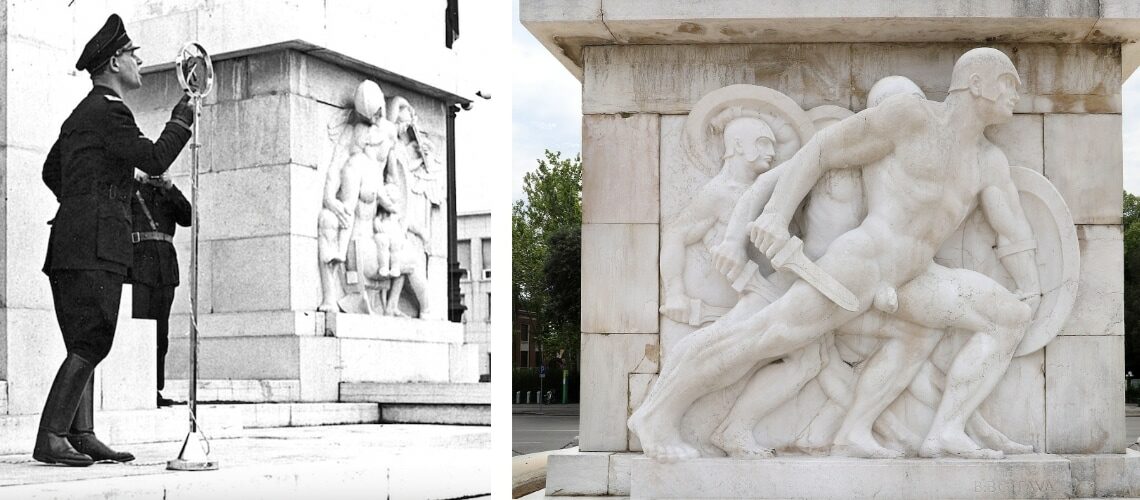

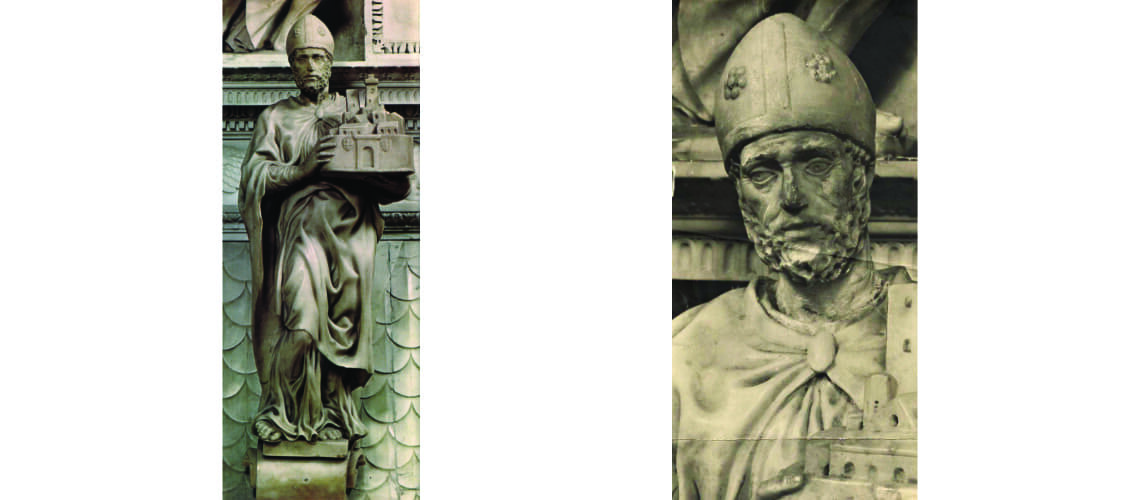

Nella formella della Porta del Paradiso in fase di cesello (Foto 12) le figure in alto sono state cesellate, quelle al centro sono a metà cesellatura, quelle in basso sono appena iniziate. Il cesello si esegue anche su fusioni di grandi dimensioni, come sulla testa di uno dei personaggi del ratto delle Sabine del Giambologna (Foto 13) e anche su quella del David di Michelangelo (Foto 14).

Foto 12

|

Foto 13 |

Foto 14 |

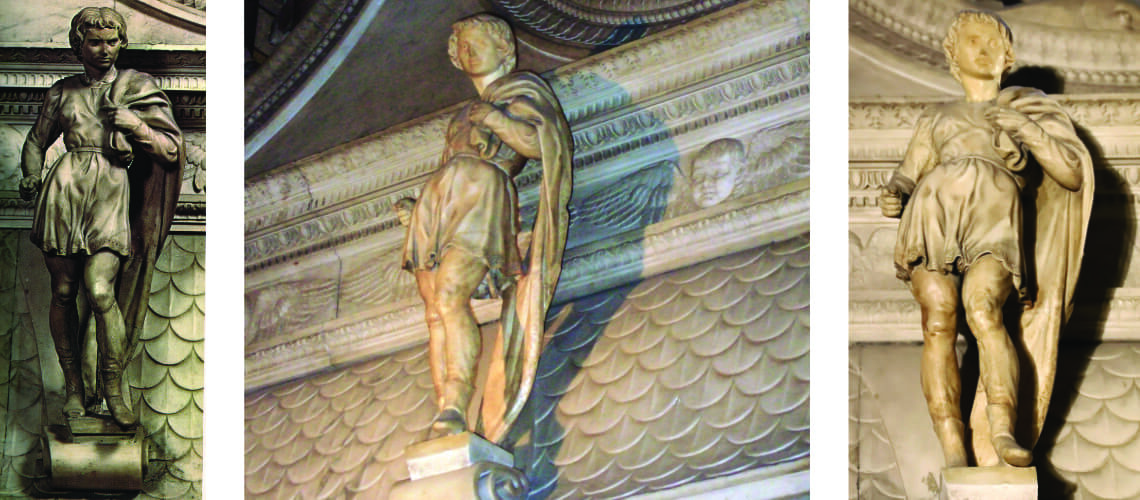

Il bordo inferiore del gonnellino del David del Verrocchio presenta un nastro con scrittura pseudo-cufica (molto di moda nel Rinascimento) eseguito a cesello (280-282). Le sottili masse dei capelli nella testa della Diana Cacciatrice del Museo Vaticano dimostrano il cesello eseguito con uno “spianatoio” (284-286).